Are High-End Japanese Woodworking Tools Really Worth the Price?

Last Updated: 12 Sep 2025

Introduction

Japanese planes (kanna) and chisels (nomi) can cost tens of thousands of yen, sometimes over a hundred thousand. For beginners, that’s far from an easy purchase.

“Cheap tools can still cut wood—so are expensive ones really worth it?”

At first glance, they don’t look all that different, so why such a big price gap? This is one of the most common questions beginners in woodworking ask.

I used to struggle to answer this myself. But after years of using both budget and high-end tools, I realised the difference lies not just in function but also in the precision of the craftsmanship, the care in the hollow grind, the beauty, and even how much the tool trains your own “eye for quality.”

In this article, I’ll share the differences I’ve noticed through personal experience. We’ll look at craftsmanship, ease of maintenance, beauty, and even investment value. Finally, we’ll ask: “So what should beginners do?”

Common Question: What’s the Difference Between Cheap and Expensive Tools?

“Are expensive planes and chisels really different?”

This is a question I hear all the time when teaching or talking about woodworking.

On Amazon, chisels and planes are sold for just a few thousand yen, while in specialty shops it’s not unusual to find planes close to 100,000 yen.

When people first see that price tag, they’re shocked and wonder: “It’s the same tool for shaving wood, so why is there such a difference?”

Indeed, whether it’s a collector’s coveted masterpiece or a modest plane from an unknown craftsman, both will cut wood, apart from a handful of truly defective pieces. At a glance, the appearance is not dramatically different. You can’t immediately see the “reason” for the high price.

I too once had the same doubts: “Does a high-end tool really perform that much better? Isn’t it just paying for the brand?” I even thought, after using a cheap tool, “Look, this works just fine.”

But over time, the difference revealed itself. Struggling with budget tools, then finding a high-end blade polished flat with surprising ease… it was only through these experiences that I began to understand: Ah, so this is where the difference lies.

So why is there such a wide price gap?

What exactly makes a tool worth over 100,000 yen?

Here are four points I’ve come to recognise.

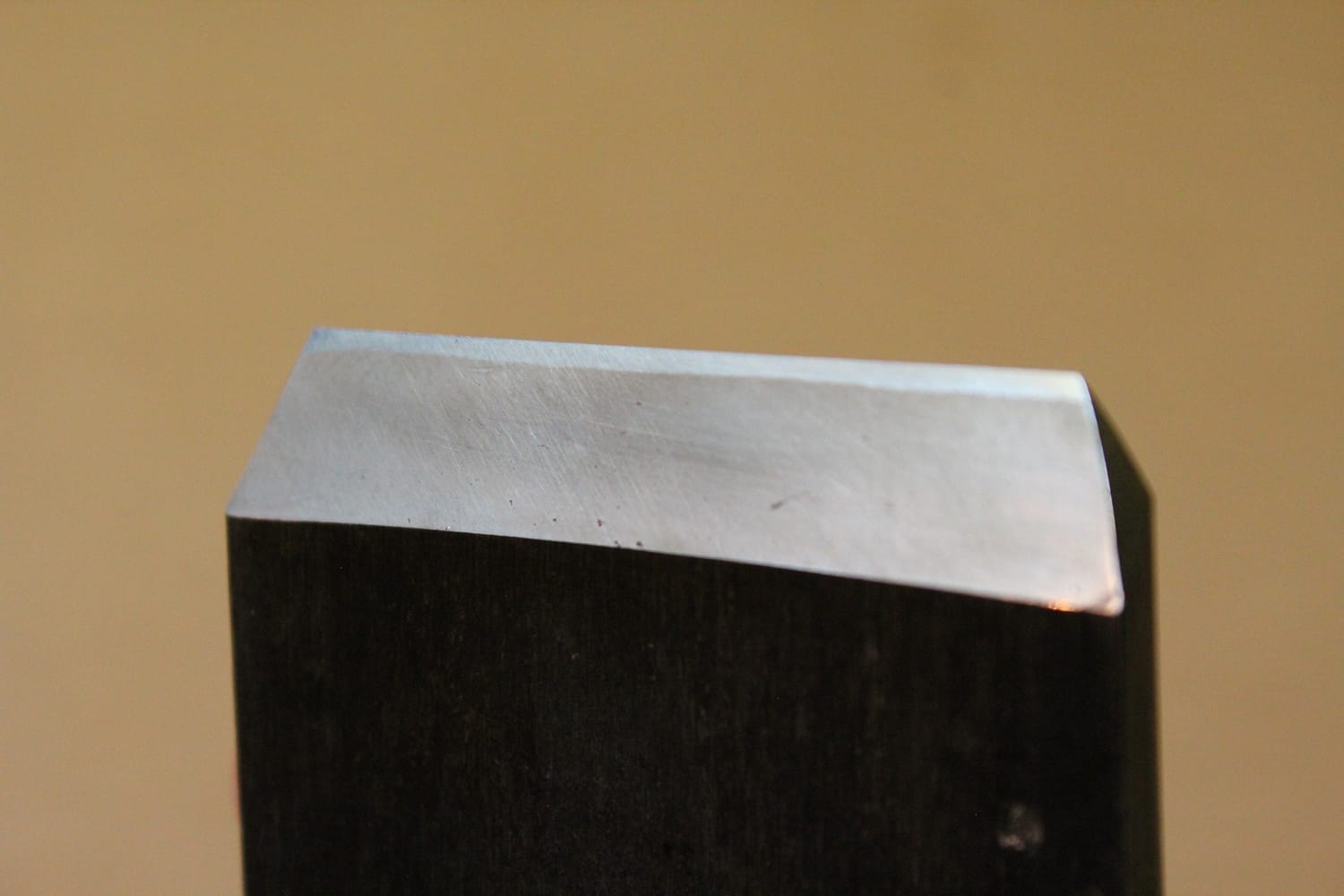

1. A Clean Seam Between Steel and Soft Iron

Japanese blades are made by forge-welding hard steel to soft iron. In high-end tools, the seam between the two metals is fairly straight and clean—a sign of good workmanship.

Of course, a wavy seam doesn’t mean the tool won’t cut. In fact, I rarely had functional issues even with cheaper tools.

But when the seam is irregular, it gives the impression of rough work. In contrast, a straight seam conveys precision and pride.

This isn’t so much a functional difference as a visible “signature” of craftsmanship. Look closely and you’ll see how quality leaves its mark.

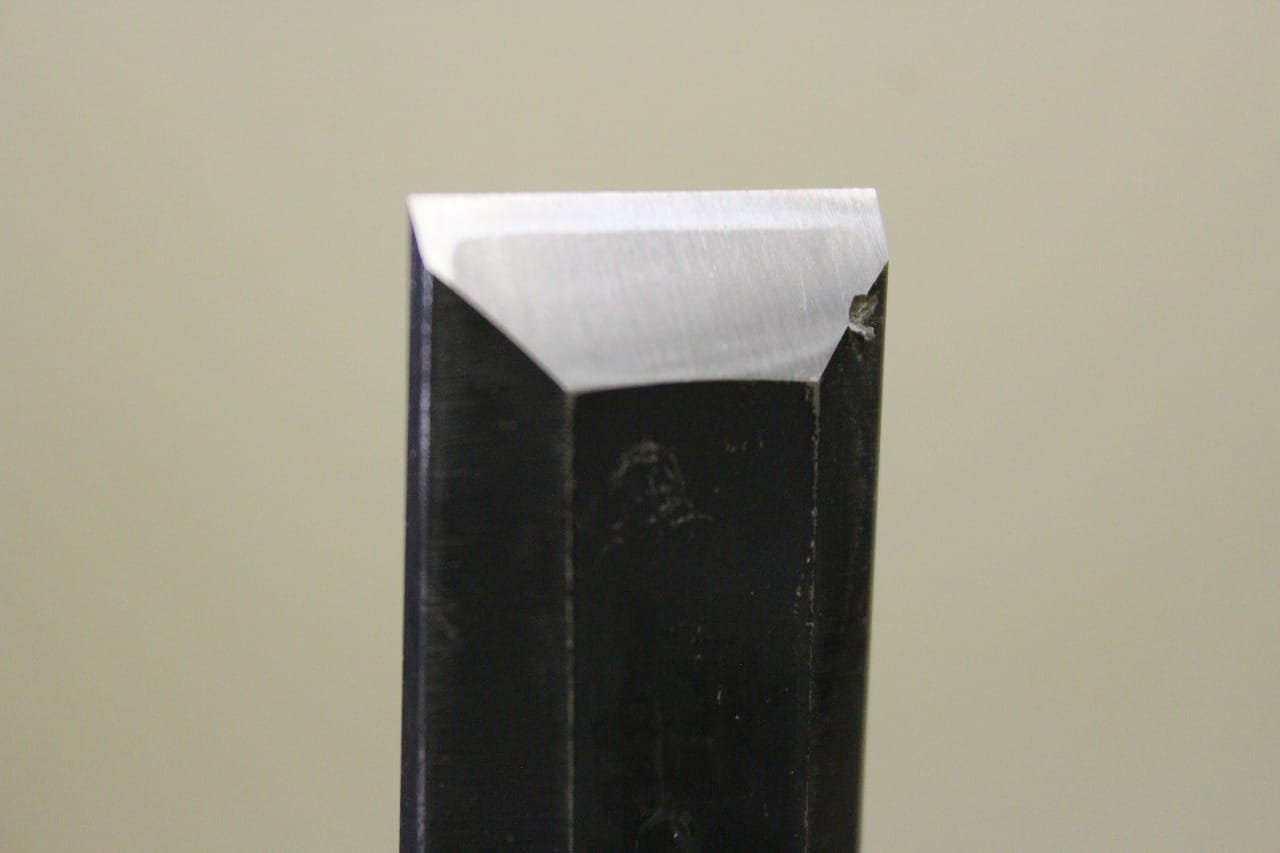

2. The “L-Shaped” Steel in Chisels

Structurally, the corners of a chisel’s cutting edge are weak points. Striking into hardwood or across a knot, force concentrates on the corners and they can chip. Anyone who has used chisels has likely experienced this at least once—it’s almost their “fate.”

High-end chisels address this by wrapping the steel into an “L-shape” around the corners. This strengthens the weakest points and also shows the smith’s commitment to detail.

Cheaper chisels often lack this feature, or it’s too shallow to be reliable. It may not cause immediate problems, but when compared side by side, the difference in craftsmanship is clear.

The presence of the L-shape is not only a matter of durability but also a marker of how much care went into making the tool.

3. Precision of the Hollow Grind (Urasuki)

A defining feature of Japanese tools is the urasuki—a hollow ground into the back of the blade. This ensures only the edge and outer rim touch the stone, making flattening (uraoshi) more efficient.

On high-end blades, this hollow is carefully formed: even in depth, symmetrical, and stable. Sharpening feels smooth, and the tool responds exactly as it should.

In cheaper tools, the hollow may be too shallow, uneven, or skewed to one side. At first it seems workable, but over time it collapses or deforms, leaving an unsightly wobble no matter how accurate your lapping plate is.

The quality of the urasuki may not be obvious at first glance, but over years of use, you realise: the back determines the tool’s reliability.

4. Refined and Beautiful Form

Another difference you can’t ignore is beauty.

High-end chisels and planes possess a kind of magnetism of beauty that transcends mere tools.

The subtle curve of a shoulder, damascus-like grain in the iron, delicate texture on the neck—details like these make the tool feel closer to fine art than steel.

This beauty is intentional. Blacksmiths don’t just make blades that cut; they also shape flow and shadow with pride. As a result, the finished tool uplifts its owner.

And beauty changes behaviour. You don’t toss it carelessly; you sharpen more carefully, maintain it with respect, and in return, the tool lasts longer. This psychological effect proves something: beauty elevates performance.

More than decoration, beauty becomes motivation. Each time you hold it, you’re reminded: I own a fine tool. That thought drives you to improve your craft.

Beauty as the True Difference

By now, you’ve probably realised: what separates high-end tools from cheaper ones are mostly aesthetic differences. A straight seam, a precise hollow, a refined form—these are signs of pride, not massive leaps in raw function.

Do they change the fact that both can cut wood? No. A skilled craftsman can still do fine work with cheap tools. I’ve made pieces with budget chisels that drew praise.

But there are differences in maintenance. Cheap tools often require extra time to prepare, with uneven hollows or warped seams making you feel “dragged around” by the tool itself. High-end tools spare you this frustration.

That absence of risk—that freedom from being at the mercy of your tools—is, in my view, the most important difference. And it leads directly to their value as an investment.

Investment Value

High-end tools are not consumables that start losing value the moment you buy them. They can carry real asset value.

Each one is handmade by a skilled craftsman

Limited production numbers ensure rarity

Retirement of a famous smith can raise prices

Some chisels and planes by renowned smiths even sell secondhand above their original price. They are working tools, yet also functional artworks.

Of course, some dismiss this: “A tool is just a tool.” But I see high-end prices as a safeguard for the craft. If tools were cheapened too much, blacksmiths couldn’t make a living and traditional techniques would vanish. In that sense, high-end tools aren’t rip-offs—they are a system that sustains the industry.

Since realising this, I’ve come to see expensive tools as an investment in culture.

What Should Beginners Do?

Reading this, you may ask: “So do I have to buy high-end tools?”

The answer is no.

For practice, Japanese tools around 10,000 yen are more than enough to train with seriously. That’s a realistic starting point.

But if you’re committed to woodworking, I recommend owning just one high-quality tool. Nurturing that tool becomes an experience in itself.

When choosing, check:

The seam between steel and soft iron

The precision of the urasuki

The thickness of the steel

And whether its beauty captivates you

If these four hold true, you won’t go far wrong.

Some even argue beginners should especially use good tools. Because good tools deliver results, and results motivate improvement. High-end tools are not unreachable luxuries—they’re an attainable investment for those taking their first steps.

I’ll never forget flattening the back of a high-end chisel: within minutes it polished perfectly flat. In that moment, I thought, “This was worth it.” That feeling is something cheap tools never gave me.

High-end tools are not luxuries. They are a blend of practicality, beauty, repairability, and cultural value. You don’t need them all—but even one genuine tool will teach you what it means to face your tools honestly.

In the end, it comes down to this: efficiency or aesthetics.

But one thing is certain: a high-end tool will sharpen your eye for quality and give unmistakable refinement to your work.

Ready for structured, in-depth training?

Latest Posts

Precision Starts with a Single Line.

Get the detailed diagrams to craft your own Japanese marking gauge (Kehiki). Start your journey with the foundational tool of Japanese joinery.

Precision Starts with a Single Line.

Get the detailed diagrams to craft your own Japanese marking gauge (Kehiki). Start your journey with the foundational tool of Japanese joinery.

About me

Hi there, I’m Hisao Zen, a Japanese woodworking artisan with 25+ years’ experience. I share the techniques and traditions of joinery through online courses, guiding beginners step by step while inspiring them to carry this timeless craft into the future.

Latest Posts

©2017–2026 DIY Japanese Joinery

All pricing is in U.S. dollars.

Some images by Freepik