White Paper Steel vs Blue Paper Steel: What Really Matters for Japanese Tools

Last Updated: 23 Feb 2026

Is White Paper Steel Better Than Blue Paper Steel?

Short answer: White paper steel is purer and easier to sharpen. Blue paper steel holds its edge longer. For traditional Japanese chisels and planes, many craftsmen prefer white paper steel for its sharpening feel and feedback.

This article focuses on Japanese chisels and planes (not kitchen knives).

Quick Comparison: White Paper Steel vs Blue Paper Steel

| Feature | White Paper Steel (Shirogami) | Blue Paper Steel (Aogami) |

|---|---|---|

| Purity | Very high (simple composition) | High (with added alloying elements) |

| Edge retention | Moderate | Higher |

| Ease of sharpening | Easier, fast to sharpen | Slightly harder, can take longer |

| Sharpening “feel” / feedback | Crisp and responsive | A bit more “damped” |

| Best for (Japanese tools) | Chisels and planes where sharpening feel matters | Heavier cutting or longer sessions between sharpening |

| Trade-off | May need sharpening a bit more often | May feel less “clean” on stones |

The Question I Kept Hearing

When I first started woodworking, to be honest, I didn’t think much of the names White Paper Steel (Shirogami) or Blue Paper Steel (Aogami). I believed that a good tool cuts well regardless of its steel type, and a bad one won’t cut well no matter what.

However, once I began teaching woodworking, I was frequently asked: “What’s the difference between White Paper Steel and Blue Paper Steel?” At first, I would answer, “It’s not something you need to worry about too much.” But since I was asked so many times, I felt the need to organise my thoughts on the matter.

In this article, I will explain the differences between White Paper and Blue Paper Steel, while also sharing my own thoughts and experiences. In the end, more important than knowledge of steel types is the attitude with which we approach our tools.

History

The names White Paper and Blue Paper Steel appeared in the 20th century. The Yasugi Works of the former Hitachi Metals, drawing from its roots in tamahagane (traditional Japanese sword steel), introduced modern steelmaking techniques in pursuit of “steel optimised for blades.”

To distinguish products, they used white and blue wrapping paper. What began as in-house naming eventually spread throughout the blade-making industry and is now recognised worldwide, almost like brand names.

White Paper Steel, with its high purity and responsiveness, became widely adopted by blacksmiths and spread as the standard material for woodworking blades such as planes and chisels. Over time, however, its very purity meant that the outcome of heat treatment was highly sensitive, and even small errors in quenching or tempering could lead to inconsistency. Blacksmiths began to seek a steel that would be more forgiving in heat treatment, offer greater resistance to wear, and deliver more stable performance across different working conditions.

In response, White Paper Steel was modified with alloying elements to improve its properties. That steel became Blue Paper Steel—born as an evolution of White Paper.

What Is Steel?

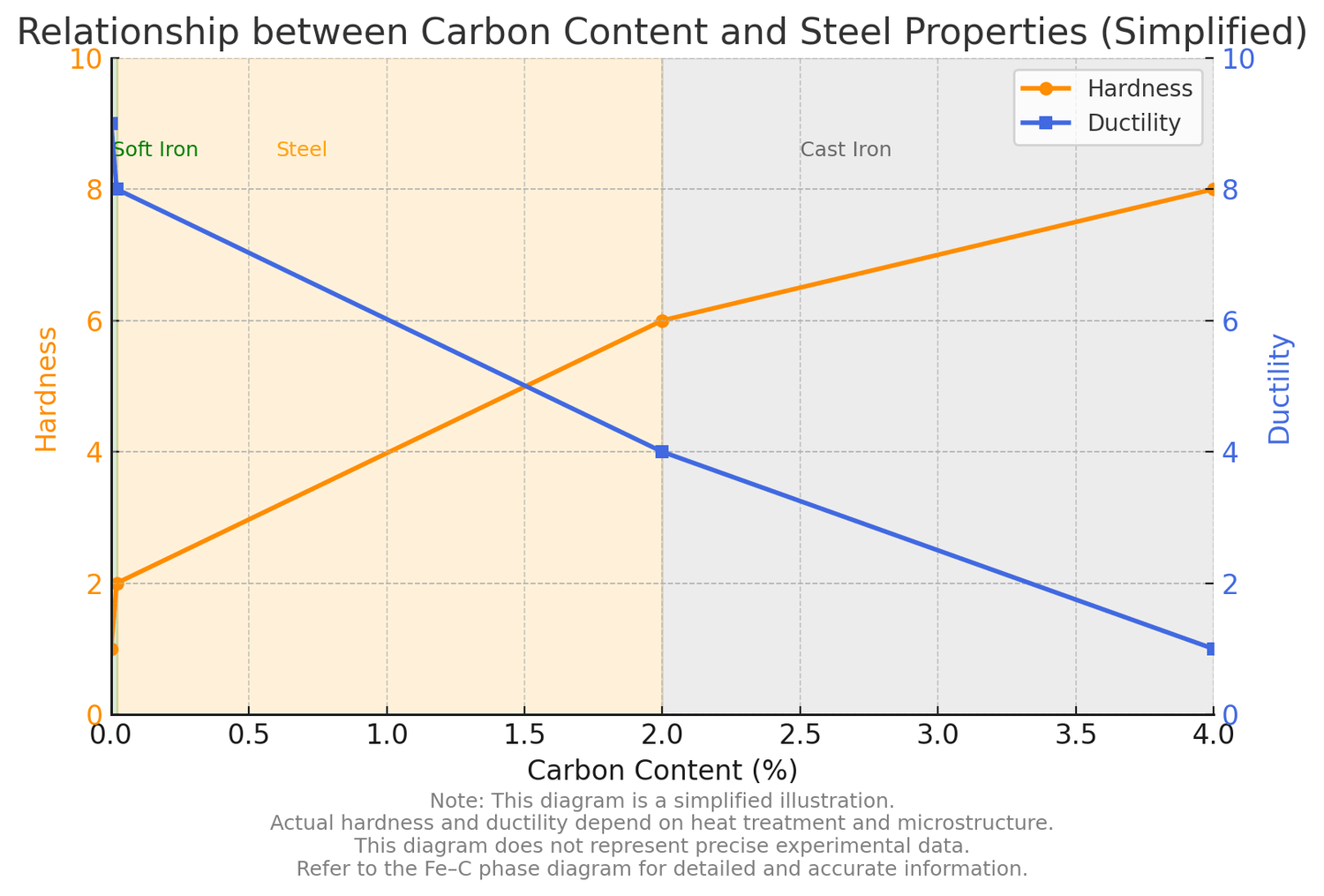

Steel is an alloy of iron and carbon. Pure iron is too soft to make blades, while too much carbon produces brittle cast iron. Steel lies in between, with 0.02–2.1% carbon, balancing hardness and toughness.

Adding carbon allows steel to transform into martensite during quenching, making it hard enough to hold an edge. Too little carbon and the edge won’t stay sharp; too much, and the edge becomes brittle and chips easily. The key lies in selecting the right carbon content and bringing out its properties through heat treatment.

This balance of carbon also directly affects sharpenability and edge retention. For that reason, precise control of carbon content has always been central to blade steel.

What Is Iron Before Carbon?

Before carbon is added, iron close to pure form is soft, ductile, and easy to work. You can hammer it thin, bend it, and it won’t easily snap. But as a blade, it cannot hold a sharp edge. Even if shaped into a knife, quenching won’t harden it enough, and the edge will quickly collapse.

Ancient people faced the paradox: “Iron is strong, yet as a blade it dulls quickly when cutting wood or bone.” What they needed wasn’t unbending strength, but the ability to stay sharp.

The solution was discovered in adding carbon. With carbon, iron became steel—hardenable by quenching, and capable of keeping a keen edge. This discovery marked a turning point, moving humanity from the “age of iron” to the “age of blades.”

White Paper Steel: Filling Iron’s Weaknesses

For blades, the key requirements are sharpness and stable performance. Japanese steelmakers therefore aimed for high-carbon steel with as few impurities as possible, carefully controlling carbon levels.

At Yasugi Works, with its long tradition of supplying steel for swords and blades, engineers pursued “steel optimised for cutting tools” by combining modern technology with tradition. The result was White Paper Steel.

Impurities like phosphorus and sulphur, which weaken edges, were rigorously removed. As a result, White Paper Steel became known as an honest, responsive steel, stable in sharpening and heat treatment. Blacksmiths embraced it as a reliable standard.

Advantages of White Paper Steel

White Paper Steel is defined by three traits: high purity, simplicity, and ease of handling. Carbon is the main player, with minimal alloying elements. This makes the effects of quenching and tempering easy to understand, giving blacksmiths confidence in achieving their intended results.

When finished into a blade, it responds lightly on whetstones, with honest sharpening feedback. You can say: “The result matches exactly the effort you put in.”

First and foremost is its ease of sharpening. On a whetstone, it grinds down lightly, making it a steel that even beginners can easily bring to an edge. Burrs also release easily, so in the finishing stage the sharpening process feels smooth and satisfying.

Furthermore, the cutting edge can be honed thin and sharp, making it easier to achieve what is often described as a “sticky sharpness”—a quality that grips the fibres rather than just slicing through them. This is one of White Paper Steel’s great appeals. Its qualities show especially well in delicate finishing work and when planing to bring out a beautifully smooth wood surface.

Because it sharpens so easily, it is user-friendly even for beginners. At the same time, however, the finished result faithfully reflects the sharpener’s skill. In this sense, it is a steel that provides meaningful feedback for everyone—from novices to seasoned craftsmen—at each stage of their development.

When working with traditional Japanese chisels and planes, steel purity affects how precisely you can control your line. Before sharpening or choosing steel, it helps to understand how traditional layout tools are structured.

Weaknesses of White Paper Steel

From the Blacksmith’s Perspective

For blacksmiths, White Paper Steel is both easy to handle and difficult at the same time. Its low impurity content means that the effects of heat treatment show up very directly, so the processes of quenching and tempering require the utmost care. If the temperature is mishandled, its hardness and toughness quickly collapse, and blade performance deteriorates dramatically.

In addition, because White Paper Steel contains almost no alloying elements, it lacks inherent resistance to tempering or wear. This means the outcome depends directly on the blacksmith’s skill. It is a “truthful” steel that tests a craftsman’s technique, but at the same time, ensuring consistent results is not simple.

From the User’s Perspective

For the user, the weakness lies in its relatively short edge retention. While it delivers a pleasant cut when working softwoods like cedar and cypress, its sharpness quickly fades when used on hardwoods or resinous timbers. For example, in planing a wide surface over a long stretch, the blade will need to be resharpened several times along the way. In other words, unless the user develops a habit of frequent sharpening and the ability to sensitively detect the blade’s condition, it is hard to fully draw out the potential of White Paper Steel.

The Development of Blue Paper Steel

“We want steel that’s easier to handle.”

“We want to sharpen less often.”

“We want blades that last longer, even on hard timbers.”

In response to these voices from the field, Blue Paper Steel was created. Based on White Paper Steel, small amounts of alloying elements were added to compensate for its weaknesses.

Thus was born Blue Paper Steel—equipped with wear resistance and strength against heat—and it spread as a steel that could better withstand professional use.

In Addition to Carbon, Blue Paper Steel Contains:

Tungsten (W), which forms hard carbides and improves wear resistance.

Chromium (Cr), which increases resistance to tempering and provides stability against heat.

In some cases, Vanadium (V) or Molybdenum (Mo) are also included, further boosting edge retention and stability during heat treatment.

These differences in composition are what separate the character of White Paper Steel from that of Blue Paper Steel.

As a Result

Blue Paper Steel excels in edge retention, and its sharpness does not easily decline even during long sessions of use. When working with hardwoods or timbers high in resin, it is able to maintain relatively stable cutting performance. It is also more resistant to tempering and offers greater stability in heat treatment, making it less dependent on the blacksmith’s skill compared to White Paper Steel.

Even today, many high-grade chisels and planes are made with Blue Paper Steel, supporting craftsmen in their daily work.

However, because of this, it is somewhat harder against whetstones, and the sharpening feel is not as light and smooth as White Paper Steel. In other words, Blue Paper Steel is best suited for a style that prioritises edge retention over ease of sharpening.

By the way, it is often referred to simply as “White Steel” or “Blue Steel.” But the correct terms are White Paper Steel (白紙鋼) and Blue Paper Steel (青紙鋼). As mentioned earlier, since the steels cannot be distinguished by appearance alone, they were wrapped at shipment in white or blue paper to identify them. Knowing this background makes it clear that the names are not just colour labels but historical names that reflect their origins.

Well then, that’s the explanation up to this point. But, Does it really help to know the difference in steel?

So, in the End, Does Knowing the Difference in Steel Really Benefit You?

To be honest, I wonder whether there is really any need to know all these details. Even if beginners or amateurs were to learn the fine distinctions in steel composition, the actual benefit they would gain in their work would likely be limited.

How Was It in the Past?

Looking back, when I first began my apprenticeship (thirty years ago), I never once bought a tool by specifying White Paper or Blue Paper Steel. Of course, I knew the names and had a rough idea of their characteristics, but knowing that didn’t mean that a beginner like me could actually feel the difference in practice.

So when I bought tools back then, the only things I really relied on were the opinions of my master or senior carpenters, and the recommendations of a trustworthy tool dealer.

These days, however, perhaps due to the influence of social media and online articles, I feel that more and more people have become strangely fixated on whether a tool is White or Blue. To be honest, when I was first asked about it, I was bewildered—“Why are people so hung up on that?” But as the same question was put to me again and again, I began to think, “I need to be able to explain this properly in my own words.” That is the reason I researched, organised, and wrote down my thoughts in this way.

Marketing by Blacksmiths

Behind this is also the marketing strategy of blacksmiths themselves. When selling blades, it is surprisingly difficult to show users differences they can immediately understand. Technical distinctions such as the precision of forge-welding or the control of quenching temperature may be clear between craftsmen, but they are not things that general customers can grasp.

In that context, the label of steel type becomes convenient. Saying “Ours is Blue Paper Steel, so it holds its edge,” or “Ours is White Paper Steel, so it has sharpness,” is simple, persuasive, and resonates intuitively even with people who lack specialist knowledge. By emphasising the difference in steel types, it can be made to appear as if the product has a clear superiority.

A blacksmith I know once put it frankly: “To be honest, the differences are small, but it’s a convenient way to explain things to customers.” In other words, the differences in steel types have functioned less as essential performance distinctions and more as “words for selling.”

As a result, the very names of steel types became established as brands. White Paper = sharpness, Blue Paper = edge retention—these images began to walk on their own, eventually being used as deciding factors in purchases. Today, more than actual steel performance, it is the names themselves that are treated as “added value.”

The Influence of the Kezurou-kai

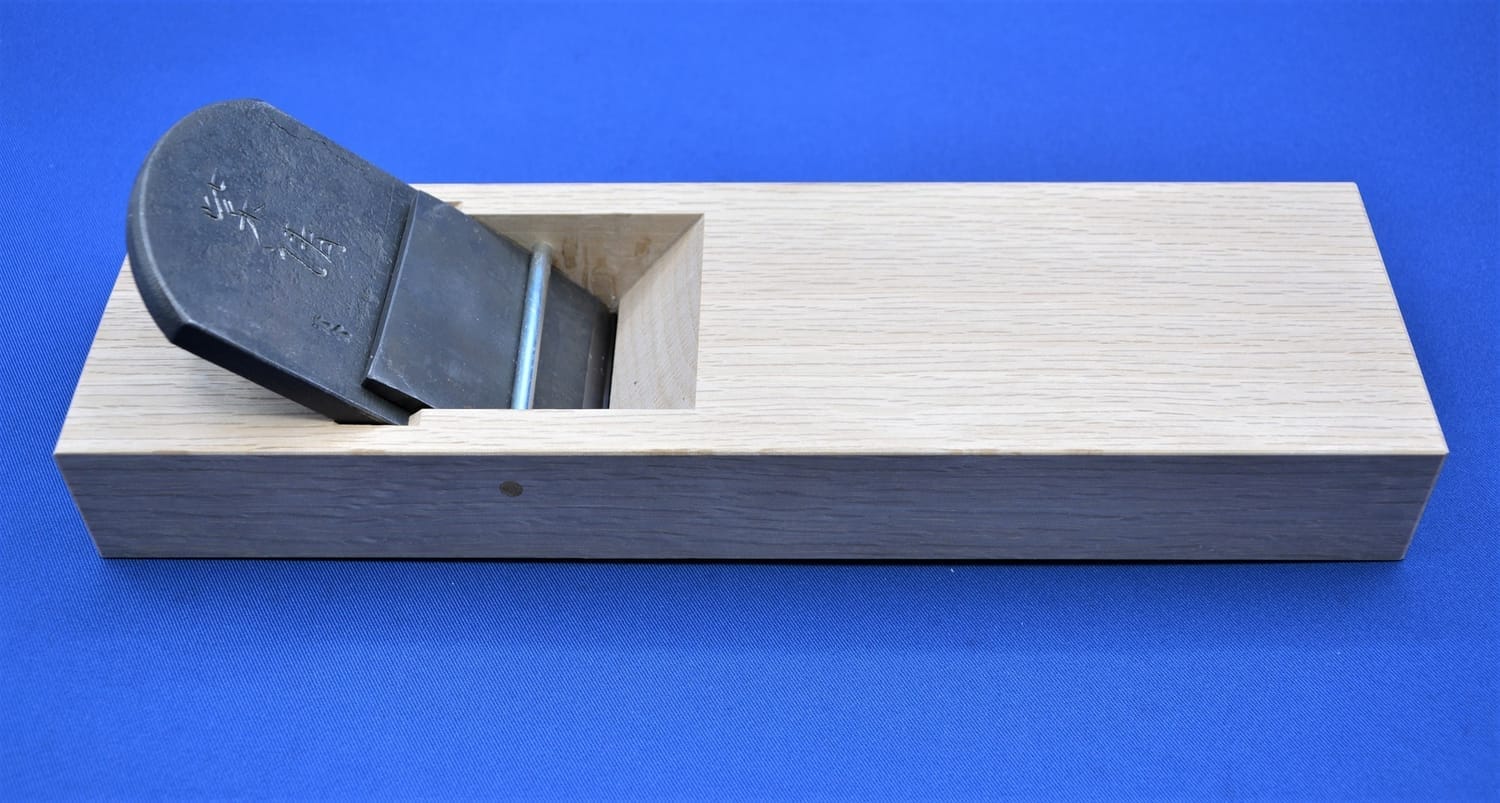

Another major factor is the existence of the Kezurou-kai (Planing Competition). This event, where people compete in the finish planing of wood, draws craftsmen and enthusiasts from all over the world and has attracted attention as a stage where shavings as thin as 0.01 mm are showcased. The thickness and beauty of the shavings are judged, and the event has played an important role in communicating the refinement of Japanese woodworking techniques to the world.

Its achievements have indeed been significant, becoming a chance for many younger generations and overseas woodworking enthusiasts to discover “the culture of Japanese planes.”

Yet at the same time, because of the competitive nature, attention naturally focused on “What steel was used?” or “Which blacksmith made the plane?” Conversations revolved around who achieved how thin a shaving with what tool, and this in turn became a trigger for steel types to be overemphasised.

Originally, the true value of the Kezurou-kai should have been in “spreading the culture of engaging seriously with wood.” However, in reality, among audiences and participants, discussions like “Blue Paper gives an advantage” or “Even with White Paper, you can shave this thin” became popular, and the labels of steel types came to walk independently as a kind of “evaluation standard.” I feel this trend fuelled the excessive interest in steel type differences.

Personal View

Even now, I feel that users do not need to know steel types in such depth. It is true that White Paper is easier to sharpen and tends to give a keen sharpness, and that Blue Paper holds an edge longer. But those differences are not so great that they manifest as decisive distinctions when you actually stand at the workbench and cut wood. If anything, they are no more than a difference in “personality.”

What actually has far greater influence on sharpness and finish is the accuracy of sharpening, the adjustment of the blade angle, and the condition of the dai (plane body). Whatever steel you use, if your sharpening is poor the edge will dull quickly, and if your adjustments are insufficient, the wood won’t cut as you wish. On the other hand, with properly honed blades and a well-prepared dai, whether it is White Paper or Blue Paper, the tool will exhibit more than enough sharpness.

In the end, what matters most is how you engage with your tools. Rather than chasing steel names, you need to keep sharpening with your own hands and listen carefully to the voice of the blade. It is this accumulation that ultimately determines the quality of your work.

Where the Difference Truly Lies

Of course, this post is not intended to be a perfect or comprehensive explanation of steel. If we wanted, we could go far deeper into technical discussions of composition and properties. But for me, writing this was a valuable opportunity to organise my own thoughts.

Knowing the differences in steel types is not useless. If you understand their names and backgrounds, they can serve as small points of reference when choosing tools. But at the same time, it’s important to understand that they do not in themselves guarantee sharpness or the quality of the finished work.

Ultimately, what determines a blade’s performance is not the name of the steel, but the day-to-day care—sharpening accuracy, blade angle adjustment, and the condition of the dai. Steel type is only a trigger; what truly matters are the hand and sensitivity of the user.

That is the message behind what I’ve written.

Ready for structured, in-depth training?

Latest Posts

Precision Starts with a Single Line.

Get the detailed diagrams to craft your own Japanese marking gauge (Kehiki). Start your journey with the foundational tool of Japanese joinery.

Precision Starts with a Single Line.

Get the detailed diagrams to craft your own Japanese marking gauge (Kehiki). Start your journey with the foundational tool of Japanese joinery.

About me

Hi there, I’m Hisao Zen, a Japanese woodworking artisan with 25+ years’ experience. I share the techniques and traditions of joinery through online courses, guiding beginners step by step while inspiring them to carry this timeless craft into the future.

Latest Posts

©2017–2026 DIY Japanese Joinery

All pricing is in U.S. dollars.

Some images by Freepik