Japanese Chisel Sharpening: Why There’s No Micro-Bevel (Nomi vs Western Chisels)

Last Updated: 1 Sep 2025

Introduction

I started woodworking with Japanese chisels. From the beginning, it felt completely natural to me that “chisels are sharpened with a single flat bevel.” Everything I learned from my mentors and books was about keeping one angle and sharpening it straight.

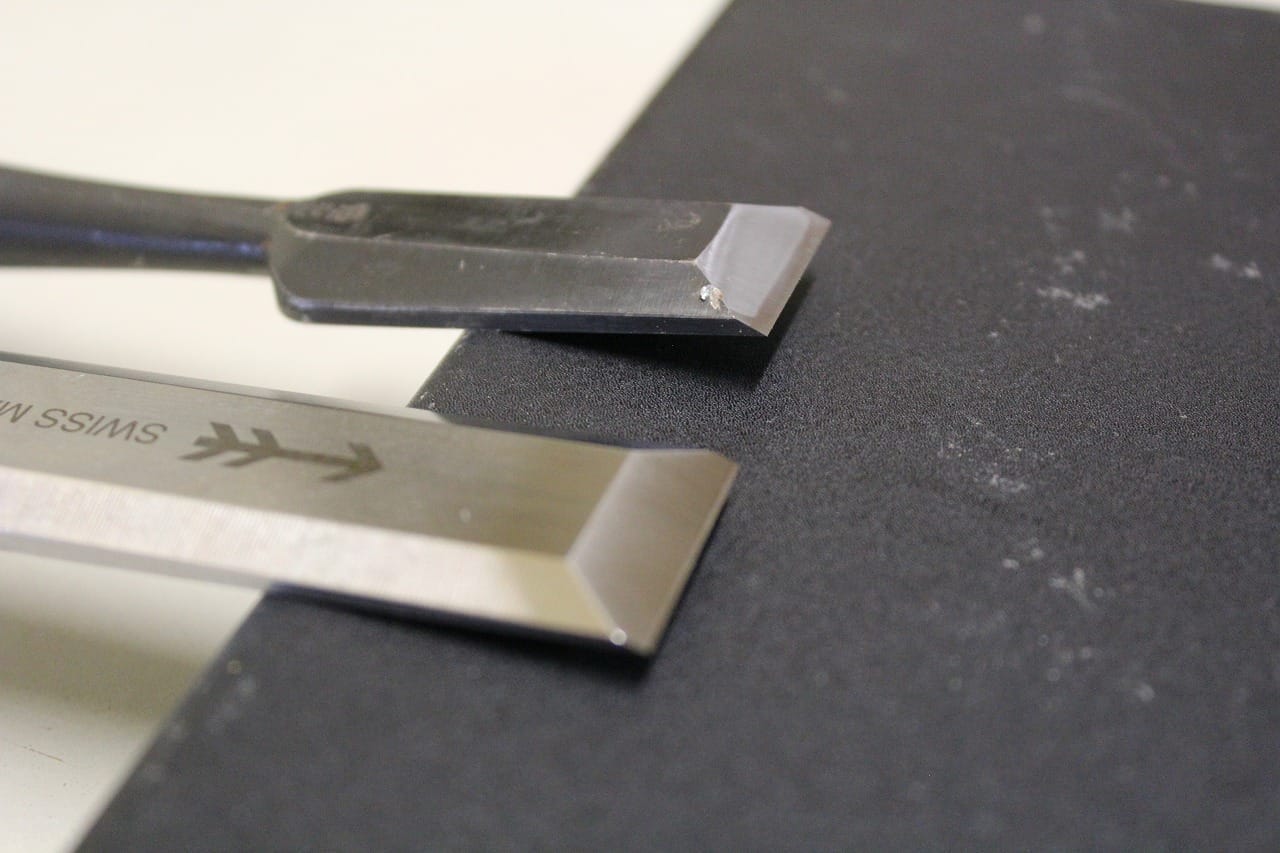

Later, I discovered Western chisels, and to my surprise, almost all of them had a micro-bevel (secondary bevel). “Wait, a double angle at the cutting edge? Who came up with that idea?” At first, I found it really strange.

In this article, I’ll share why Japanese chisels traditionally don’t use micro-bevels, the background behind it, and how it differs from Western tools—mixed in with my own experiences and impressions.

What Is a Micro-Bevel?

First, let’s define it clearly.

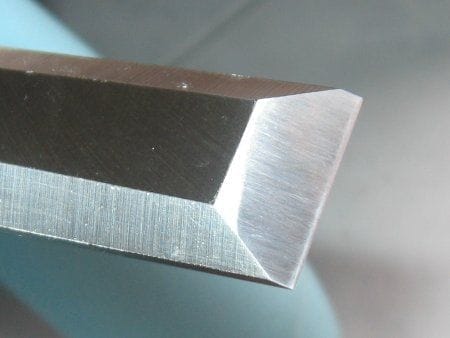

A micro-bevel is a tiny change of angle added to the very tip of the main bevel (the sloped face of the blade). By slightly steepening the angle of the blade just a few degrees, you create a small secondary bevel that differs from the main sharpening angle.

Why Add a Micro-Bevel?

When I first sharpened a Western chisel, what struck me most was: “This is fast!” That’s exactly what micro-bevels are for.

Advantages of Micro-Bevels

Sharpening efficiency

You only need to touch up the very tip, instead of grinding down the entire bevel every time. I really felt the difference in speed.Easy angle adjustment

If you’re working hardwood, you can quickly raise the micro-bevel a few degrees. It’s simple and effective.

To me, Western chisels represent a tool culture built around efficiency and versatility—being able to adapt to different woods with minimal effort.

So Why Are Japanese Chisels Single-Bevel?

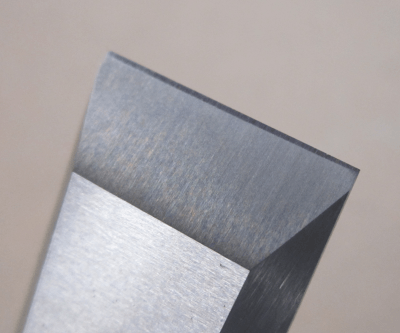

In contrast, Japanese chisels are traditionally sharpened with a single bevel. For me, this was the “default” way of working.

Design Philosophy

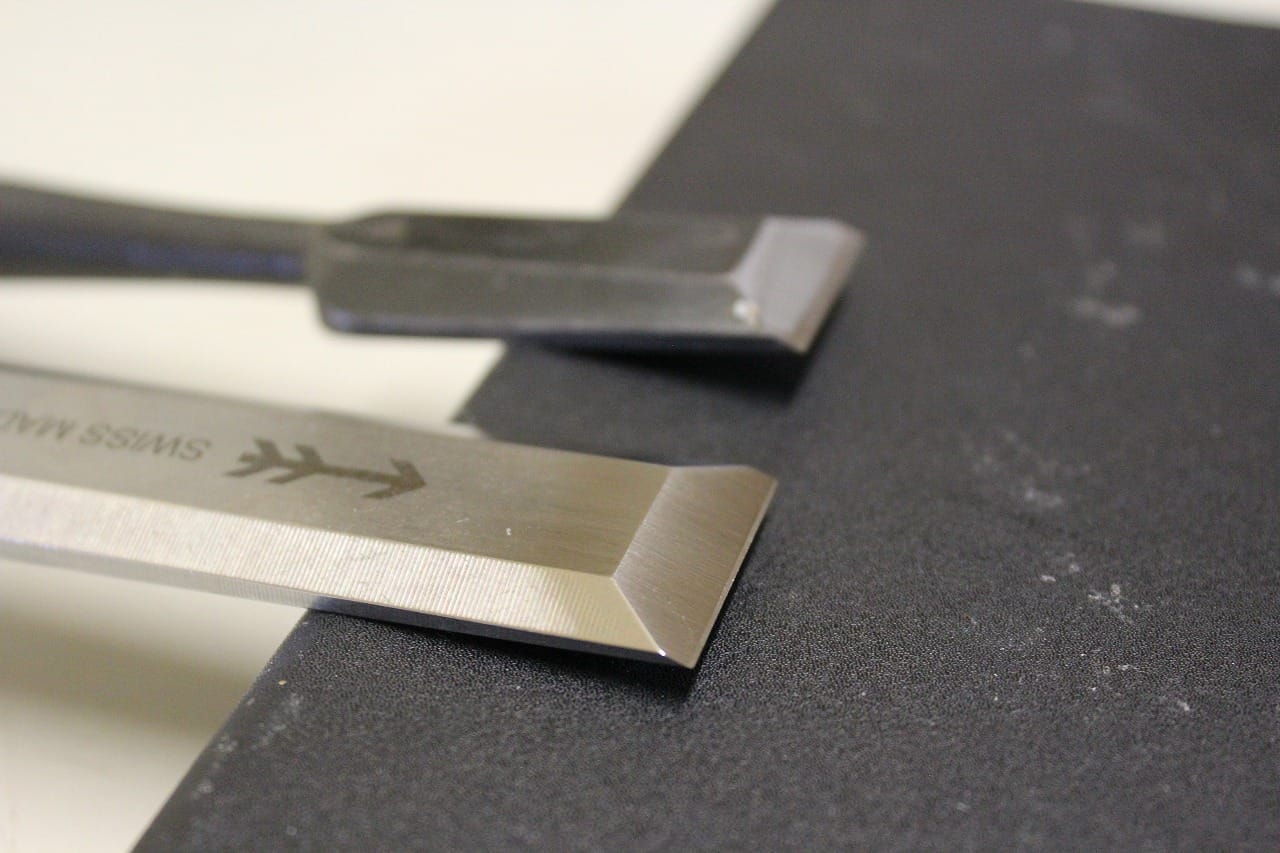

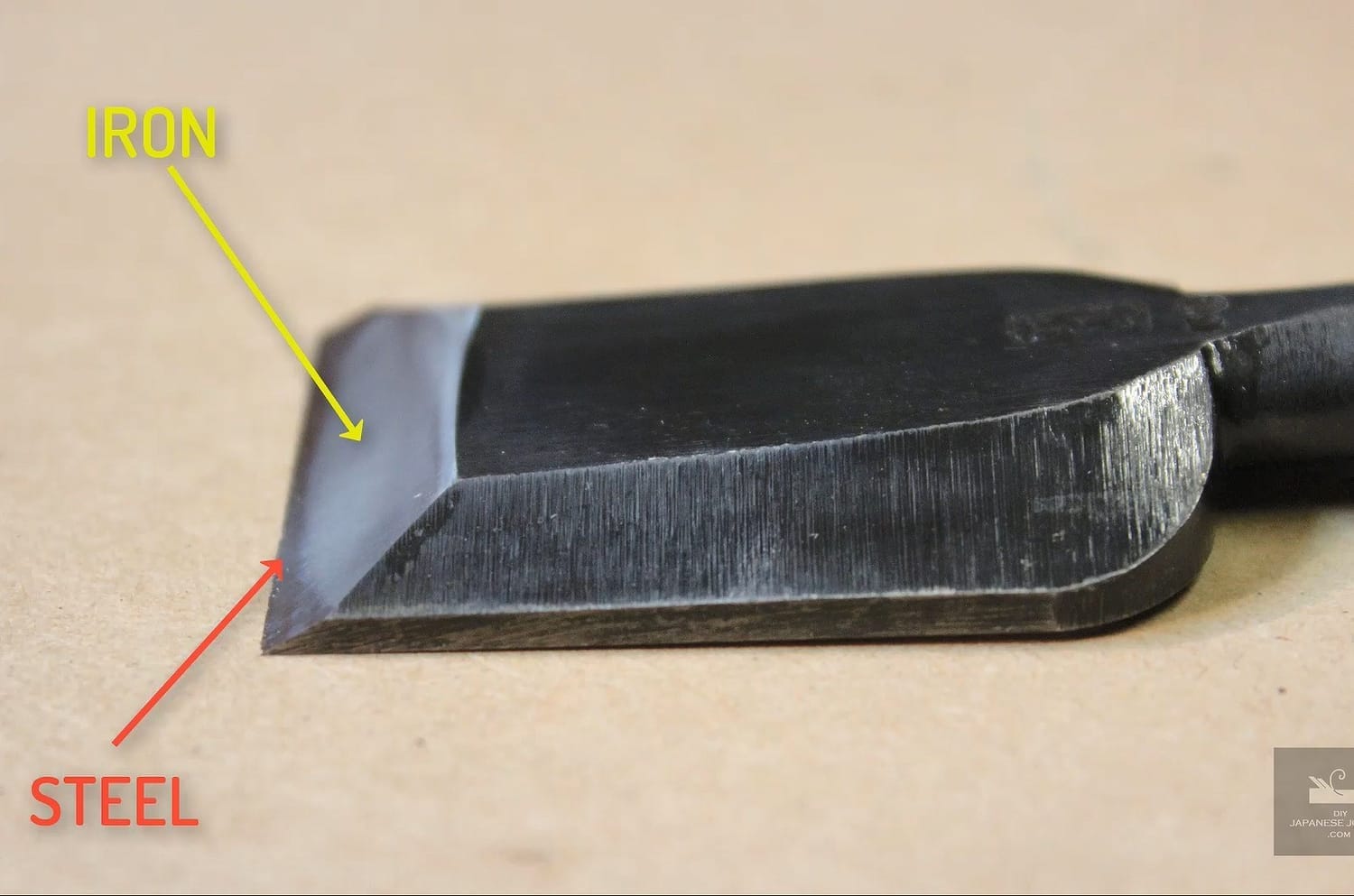

Japanese chisels are made of a laminated structure: hard steel at the edge supported by soft iron. Thanks to this design, sharpening the full bevel is not a heavy burden, and you can maintain both strength and sharpness.

That’s why the idea of adding a secondary bevel never really took root—it simply wasn’t necessary.

Relationship with Wood

It’s true that Japanese carpentry was largely based on softwoods like sugi (cedar) and hinoki (cypress). But hardwoods like keyaki (zelkova) and nara (oak) were also commonly used. So why no micro-bevels even then?

Because the common practice was either to adjust the sharpening angle depending on the wood, or to keep separate chisels for different uses.

Personally, when I cut hinoki, I keep the angle shallow for easy entry. When I work on hardwoods, I raise the angle slightly. For me, “adjusting through sharpening” has always felt natural.

Sharpening Culture

What really sets Japanese chisels apart is cultural. I was taught—and many craftsmen believe—“a blade must be sharpened straight, with one consistent angle.” Keeping that single angle is not just technique, but a kind of pride.

When I sharpen a flat bevel, I feel like I’m facing the tool honestly. Micro-bevels may be convenient, but to me they always feel a little like a shortcut.

Cutting Feel

Some people say that a micro-bevel dulls the sense of a blade “biting straight into the wood.” This is subjective, but I agree. For me, a single bevel feels cleaner and more direct when cutting into timber.

What Happens When the Wood Changes?

This is probably the biggest question.

With Western chisels, you just tweak the micro-bevel and you’re done. But how do Japanese craftsmen handle it?

The answer comes in two main approaches:

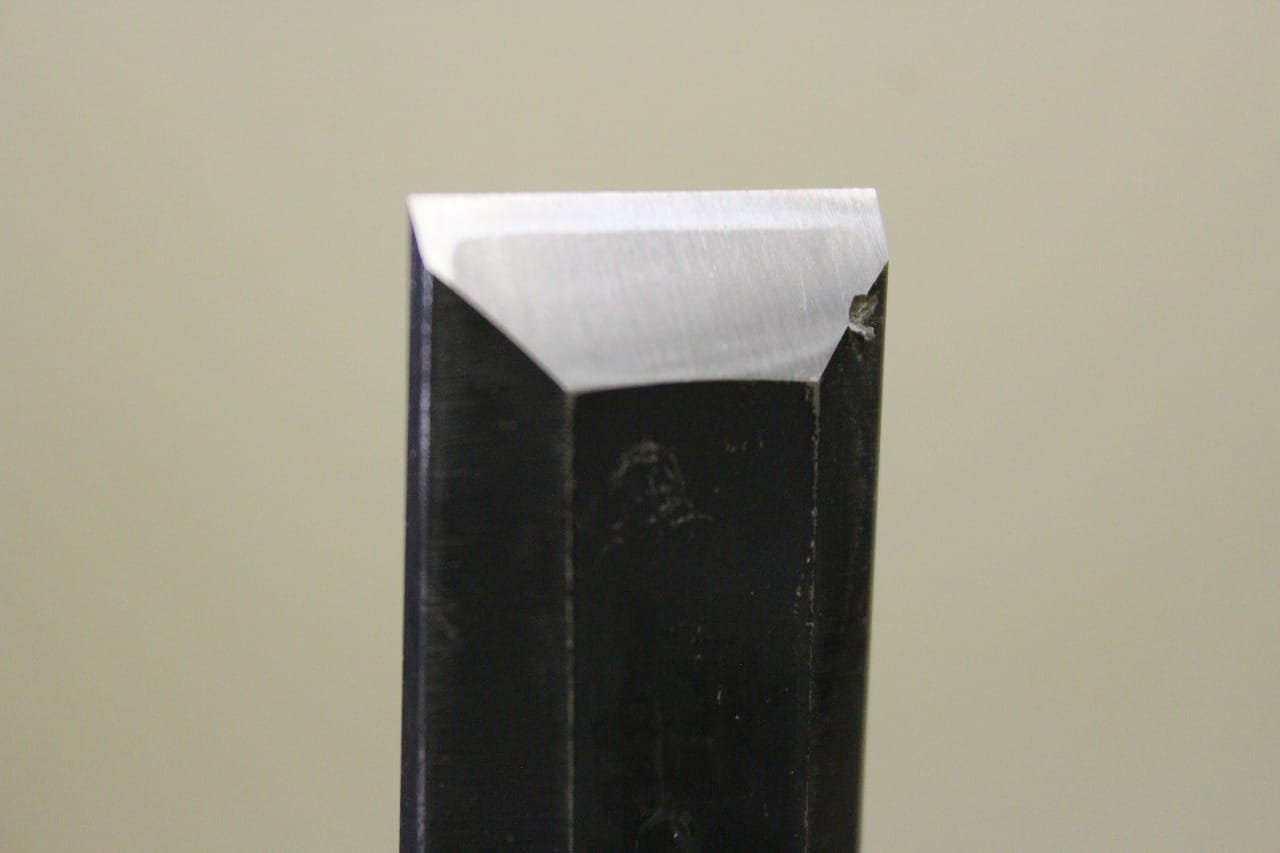

1. Change the sharpening angle depending on the material

Shallower for softwoods, steeper for hardwoods. One chisel can be adapted with careful sharpening.

2. Keep separate chisels for different uses

Since it’s too time-consuming to regrind the full bevel every time, many craftsmen prepare chisels sharpened at different angles:

For softwoods: shallow angle, glides easily into hinoki (cypress) or sugi (cedar).

For hardwoods: steeper angle, strong enough to withstand keyaki (zelkova) or nara (oak) without chipping.

I also prepare a “hardwood chisel” when I expect to work with tough material. In the end, Japanese practice isn’t about efficiency or flexibility—it’s about preserving the single-bevel philosophy and the aesthetic behind it.

Common Misunderstandings

“You must never add a micro-bevel to a Japanese chisel.”

→ There’s no such rule. Some modern craftsmen add one when working hardwoods. I’ve tried it myself, and yes—it is efficient.“A micro-bevel always makes the edge sharper.”

→ Not true. Sharpness comes from the angle and the balance with the wood. The micro-bevel is about efficiency, not magic sharpness.

Conclusion / Takeaway

Here’s my conclusion:

Micro-bevels have logical reasons: faster sharpening, quick adjustment for hardwoods.

Japanese chisels have continued with a single bevel not because of efficiency, but because of an aesthetic: the belief that “a blade should be sharpened straight, with one true angle.”

In the end, it comes down not just to logic, but to culture and values.

The West values efficiency; Japan values the purity of a single bevel.

I can understand both, but personally, nothing compares to the feeling of a Japanese chisel slicing straight into the wood.

Ultimately, it’s not about which is “correct,” but which philosophy resonates with you.

Ready for structured, in-depth training?

Latest Posts

Precision Starts with a Single Line.

Get the detailed diagrams to craft your own Japanese marking gauge (Kehiki). Start your journey with the foundational tool of Japanese joinery.

Precision Starts with a Single Line.

Get the detailed diagrams to craft your own Japanese marking gauge (Kehiki). Start your journey with the foundational tool of Japanese joinery.

About me

Hi there, I’m Hisao Zen, a Japanese woodworking artisan with 25+ years’ experience. I share the techniques and traditions of joinery through online courses, guiding beginners step by step while inspiring them to carry this timeless craft into the future.

Latest Posts

©2017–2026 DIY Japanese Joinery

All pricing is in U.S. dollars.

Some images by Freepik